The Building of an On-Orbit Sensor

by Carol Bruegge, May 1996

A space satellite is useful only because of the various sensors, or instruments, that it carries. This brief article tells what happens during the building of a typical sensor instrument. It is based on the experience we have had with the Multi-angle Imaging SpectroRadiometer (MISR), and mentions specific aspects of the MISR activities. The overall story is similar to that of building any on-orbit sensor, -- some are much more complex and more expensive than MISR, while others are much simpler and correspondingly less expensive, depending on the requirements.

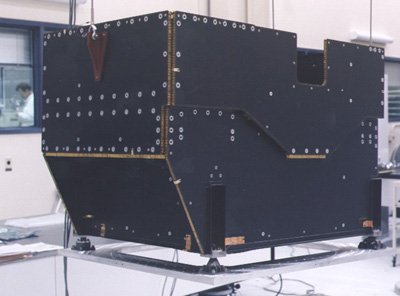

This photograph shows the major internal mechanisms of MISR, assembled ready for testing. At the core of the assembly is a "chassis" called the optical bench, which is built with extremely high mechanical precision for mounting the optical components. The cameras (one is visible, like a canister pointing downwards) are mounted directly on the optical bench. Also shown are the arms carrying the diffusion panels (the panels are visible at the top, one at the front and one at the rear.

NASA Photo ID: AS08-16-2596

Building the instrument

Each of the EOS spacecraft sensors, or instruments, has been designed and built to meet unique specifications. In this sense they are each a custom design, tailored to a specific scientific application. For MISR, over 100 individuals were assigned to the task. At the lead is a chief scientist, known as the "Principal Investigator." He works with team of scientists, the "Science Team", to define the specific data products desired from the instrument's on-orbit data. The desired scientific applications, and the way that the data received from the instrument will be structured and processed, become the basis for an overall design concept, and later are used to develop performance requirements that guide the details of the instrument design.

Design specialists using computer-aided drafting software then draw the instrument concept and the parts required, defining the parts to less than a thousandth of an inch accuracy. Engineers guide the formation of the drawings and specify materials and thicknesses to achieve the balance between stiffness and weight. Machinists use the drawings to cut metal and plastic parts to highly precise tolerances, and technicians assemble these parts to make component sections that form the instrument. These sections are called subsystems of the instrument, and consist of assemblies such as lens barrels, detector packages, electronics, and computers.

Another technician team assembles the various subsystems into a working instrument. The instrument is then tested thoroughly to ensure that it will function in space as required. Scientists and data analysts develop computer tools that will be used to view the images made during the testing of the instrument. These computer tools will then be used to interpret the images received from the instrument when it is orbiting around Earth.

Where the instrument is built

The main center of operations where MISR is being built is a facility called the High Bay. This is a huge room dedicated to the assembly and test of the instrument. The MISR High Bay is 50 x 100 feet, and 30 feet in height. The biggest challenge to this facility is that of maintaining a clean environment. An air circulating system moves filtered air from the ceiling to the floor. Small particles are removed, so that less than 10,000 particles per cubic foot of air remain.

The biggest source of contamination to the room occurs when humans enter. The human body sheds up to one million hair and skin cells per minute!! Because of this the engineers and technicians who work in this room wear special garments. Booties cover the shoes, a jump suit covers the clothes, arms, and legs. A face mask and rubber gloves are worn, as well as a hat to cover the hair. These garments are specially designed and laundered. Carbon fibers in the garments prevent the humans from damaging the instrument with static electricity. The material is lint-free. Access to this room is limited. The people who work in this area not only have to dress in the garments described here, but as they enter, they also must take an "air shower" in a small chamber which sends jets of air streaming out onto them at many heights.

Why great care is required

Why is all of this care taken? It must be remembered that the space environment is very different from that here on Earth. The biggest concern is that the stronger UV light in space will harm the instrument. You might have learned that the ozone layer of Earth absorbs UV light that would otherwise be damaging to the eyes and skin of humans. Well, in space this UV absorption has not occurred. The energy within this light can be damaging to space instruments as well. A mere fingerprint on a camera lens turns black when exposed to the UV light in space, thus preventing the camera from taking the images they were built to take. Another concern is that the MISR instrument is made of many microcircuits. A small particle of dust could make the electronics malfunction. The individual detectors are less than 1/1000th of an inch in size!!! This can be compared to the size of a human hair. A small dust particle lying on a detector could make the camera inoperative.

Testing the sensor

Instrument testing must verify that the cameras will work even after undergoing the stresses of the launch, the vacuum conditions of space and extreme temperature changes that occur when the instrument orbits in and out of the sun (when it goes behind Earth.) Thus, the test facilities include test chambers where air can be removed to form a vacuum and the temperature can be lowered or raised. The instrument is also fastened to shake tables that can simulate the shocks and vibrations that are encountered during launch.

The extent of the testing is driven by the knowledge that there is no way to bring an instrument such as MISR back to Earth for repair. The Hubble Space Telescope repair was made possible because the spacecraft was in a relatively low orbit, accessible to the shuttle astronauts. However, as well as flying higher, the MISR instrument will be in a polar orbit, i.e., passing over the North and South Poles rather than around the Equator after the fashion of the Space Shuttle. It will thus never be possible to retrieve or repair MISR after it is launched.

Launching the sensor, the start of the mission

The launch of the instrument like MISR thus follows five years of design, two years of building and testing, and millions of dollars funding. When the first images from these on-orbit sensors are received at stations on earth, it is a day to celebrate. The collected images represent an end to a decade of preparation. Ten years of planning, designing, building, and testing have been performed to ensure the instrument can withstand a rough launch and harsh space environment and still send back the information desired. The first images received are the beginning of the era of scientific investigation and learning for which the instrument was planned and built.